Innovative Manufacturing Solutions

Additive Manufacturing & Investment Casting

With over 35 years of combined experience, Strataforge is dedicated to delivering world-class manufacturing solutions. Our expertise spans additive manufacturing and investment casting, allowing us to offer innovative, cost-effective prices on single items and batch items . By using advanced technologies such as SLA printing, we minimize costs, accelerate lead times, and optimize the production of intricate components. At Strataforge, we specialize in seamlessly integrating diverse processes into cohesive, efficient manufacturing workflows. Contact us today to discover how we can bring your ideas to life.

-

DESIGN

- Using advanced 3d modelling software like SolidWorks and Fusion 360, we create detailed models for everything from prototypes to full production runs. Serving industries like healthcare, automotive, and consumer goods, our design process ensures accuracy, flexibility, and rapid turnaround times.

- Strataforge offers the ability to tailor your designs to precise requirements, effortlessly transforming concepts into practical applications via our additive manufacturing services.

-

PRINT

- At Strataforge, Fused Deposition Modelling (FDM) plays a vital role in our additive manufacturing capabilities. We produce high-quality prototypes and functional parts with exceptional durability. Using materials such as PETG, PLA-CF,TPU, and Nylon.

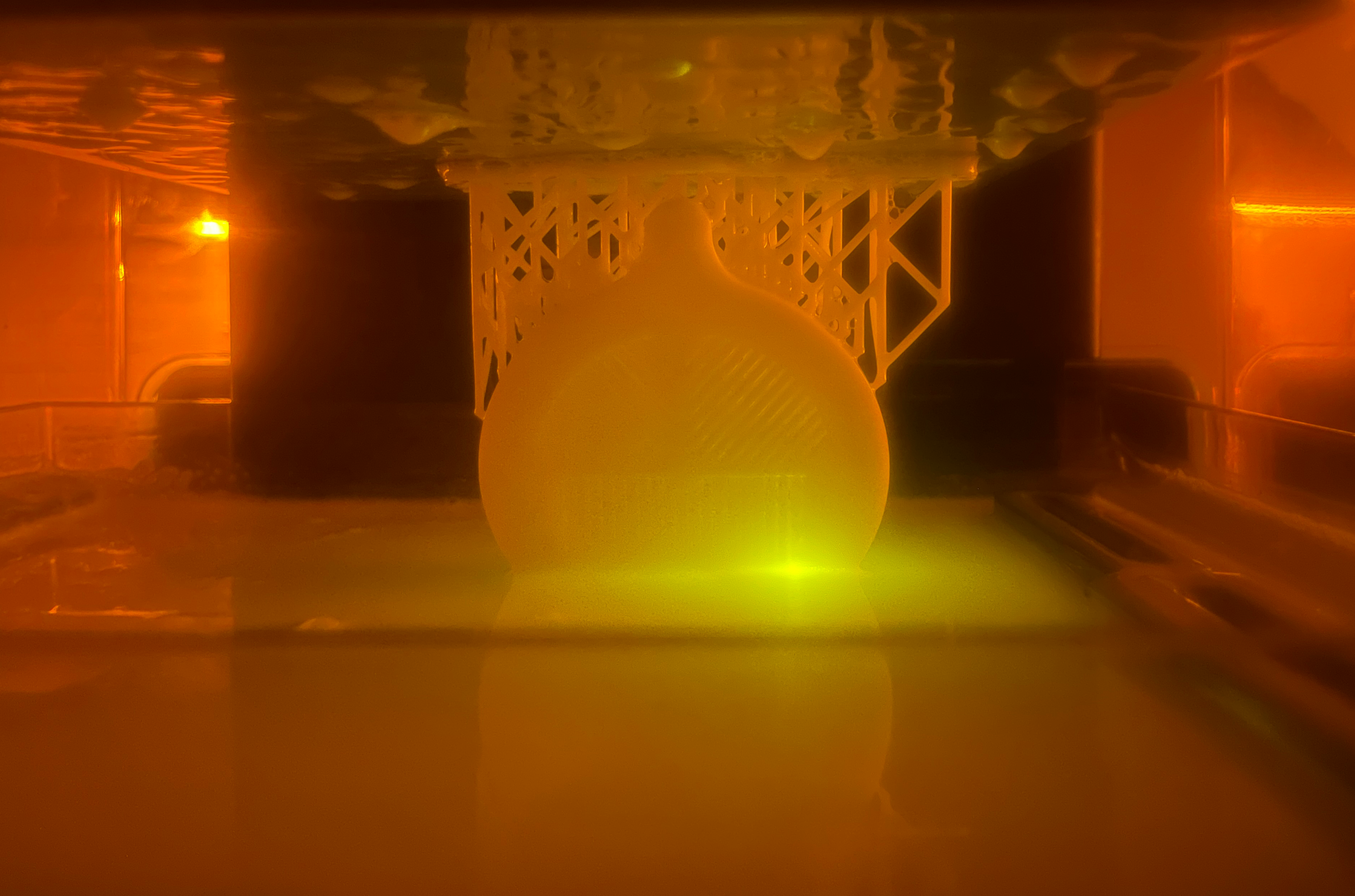

- Strataforge specializes in SLA printing, a cornerstone of our additive manufacturing expertise. Renowned for its precision and intricate detailing, our SLA printing utilizes cutting-edge photopolymer resins to create highly accurate components. This technology is ideal for demanding, and complex designs requiring smooth finishes and detailed geometries.

-

CAST

- We specialize in non-ferrous investment casting, with a casting weight capacity of up to 30kg, we excel in producing complex and detailed parts using non-ferrous alloys such as aluminium, bronze, and brass.Our investment casting process ensures excellent dimensional accuracy, surface finish, and material integrity, making it ideal for precision engineering applications in aerospace, automotive, marine, and industrial machinery.

- We handle both small and large production runs, offering design flexibility and the ability to cast intricate geometries that meet the most demanding specifications.

1

/

of

3

-

BAHTINOV MASK (CUSTOM SIZE)

Regular price From £5.50 GBPRegular priceUnit price / per -

DEW & LIGHT CAP (CUSTOM SIZE)

Regular price From £5.50 GBPRegular priceUnit price / per -

TELESCOPE DIFFRACTION CAP (CUSTOM SIZE)

Regular price From £5.50 GBPRegular priceUnit price / per